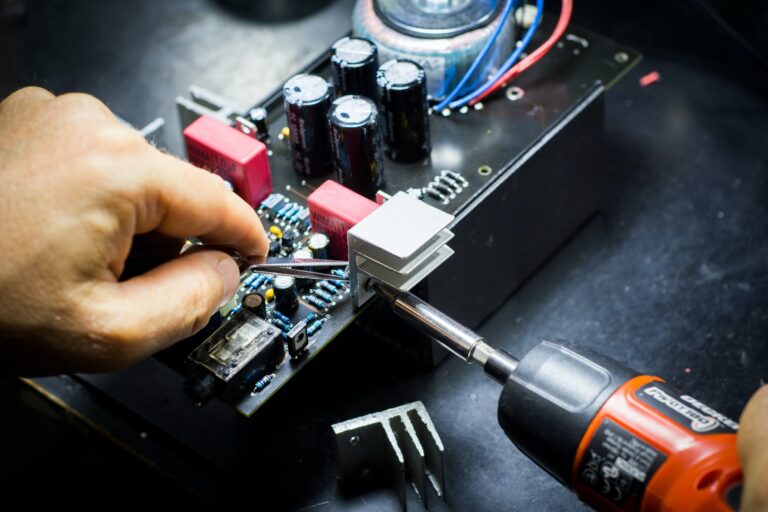

Standardization has made the mass production of electronics possible for more companies than ever before. With standardized components, not every company needs its own electronics production line – they can find compatible parts off the shelf or out in the marketplace for nearly anything they want to create.

Computers, home appliances, IoT devices, and even medical equipment are all feasible because their creators can find components like semiconductors, CPUs, and displays available at reasonable costs.

Here, we’ll cover the benefits of standardizing electronic components in product development.

Interoperability and Compatibility

The ability for different components to work seamlessly together and exchange information effectively is what we mean by interoperability and compatibility. When electronic components are standardized, interoperability becomes easy.

Engineers working with such components can confidently select and incorporate parts from different manufacturers provided the selected components are standardized.

These electronic components adhere to universally recognized designs and recommendations, which allows for seamless integration with other devices and systems that boost the overall compatibility of the final product.

Reduced Development Time and Costs

Unlike custom-built electronic components for each project, with standardized electronic components, manufacturers can leverage pre-existing designs, libraries, and documentation associated with these parts to save valuable time and resources and achieve lower costs and faster time-to-market.

Additionally, the bulk production of these components lowers costs that translate into savings for manufacturers and consumers.

Reliability and Quality Assurance

You always want to have a reliable electronic component and the way to ensure this reliability is if these components meet rigorous testing procedures, manufacturing guidelines, and performance benchmarks.

You won’t have to worry about quality and reliability using standard components because they go through testing procedures to ensure quality. The same cannot always be said for non-standardized components.

Ease of Maintenance and Upgrades

It is a lot easier for you to perform repairs, maintenance, and future upgrades to products with standardized components. This is simply because, when such components are used, replacement parts are readily available, and upgrading or modifying such a product becomes straightforward.

This flexibility is invaluable, especially in industries where technology evolves rapidly, enabling manufacturers to adapt their products to meet the changing market demands without undergoing complete redesigns.

Global Supply Chain and Availability

Using standardized electronic components will make your supply chain more resilient and robust since these components most likely have wide adoption and acceptance.

By using them, you minimize the risk of supply chain disruptions due to factors such as geopolitical events, natural disasters, or sudden changes in demand because, if any of those disruptions happen, you can source components from different regions, reduce dependencies on a single supplier and enhance your supply chain’s resilience.

Regulatory Compliance

These components are built with regulatory requirements and certifications in mind otherwise, they wouldn’t pass the standardization tests. This is a huge advantage because, with them, you don’t have to worry about their compliance or whether your product meets the necessary safety, quality, and environmental standards.

This is particularly crucial in sectors such as aerospace and healthcare, where strict standards and regulations govern product development.

Enhanced Documentation and Support

Documentation like datasheets, application notes, and guidelines for these components is also standard which you will find useful when comparing multiple components from different manufacturers.

With well-documented information, the integration, troubleshooting, and maintenance processes also become simple which makes for a more efficient and informed development cycle.

Furthermore, you can even find alternative information sources like online forums, YouTube channels, Facebook groups, and Instagram pages where experts with knowledge of these standard components can help you in case any issues arise.

Technology Scalability

Think of technology scalability as the ability of a product or system to efficiently accommodate and adapt to changes in technology, especially as advancements occur.

Standardized electronic components often follow modular design principles, allowing for the creation of systems with interchangeable parts. This modular approach enhances technology scalability by enabling developers to replace or upgrade specific modules without affecting the entire system.

As technology evolves, new versions or generations of standardized components are also released, offering improved performance, additional features, and increased efficiency.

Simplified Procurement and Inventory Management

Most reputable wholesale distributors and suppliers will readily have standardized components which will help you reduce lead times and procurement complexities.

Additionally, these components also enable better inventory management as engineers can maintain a standardized stock of components applicable across multiple projects, minimizing excess inventory and reducing the risk of obsolescence.

Customer Trust and Confidence

Using components that adhere to established industry standards can instill confidence in your customers regarding the performance and interoperability of your final product.

You need this trust when building brand reputation and customer loyalty, as customers are more likely to choose products and brands that are perceived as reliable and compatible with other devices.

In case you have found a mistake in the text, please send a message to the author by selecting the mistake and pressing Ctrl-Enter.